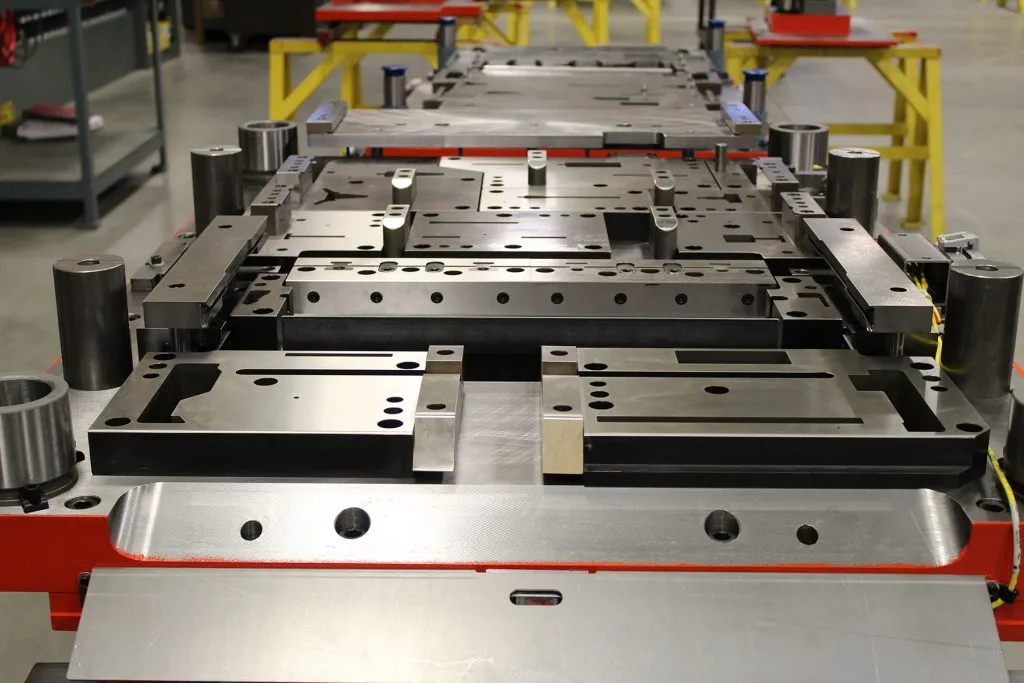

Metal stamping is a highly efficient process that utilizes stamping presses and dies to form metal sheets into the desired shape. In addition to its efficiency, metal stamping is known for producing complex parts that adhere to tight tolerances and specifications with optimal repeatability. Because of this, metal stamping has become an essential element in the automotive industry, particularly for electric vehicle (EV) manufacturing.

Automotive metal stamping has grown in popularity within the EV space due to its ability to produce intricate, lightweight components that reduce fuel consumption and carbon emissions. EV stamping also offers a solution for producing parts with optimal material efficiency and cost-effectiveness. At ESI, we understand the challenges our automotive customers face and offer a range of manufacturing services and engineering solutions to meet the industry’s strict requirements. Utilizing innovative technologies like Geogrid in our automated systems, we can deliver safety-critical EV parts with optimal speed, quality, and efficiency.

EV Stamping Industry Applications

Metal stamping, integrated with advanced technologies such as Geogrid, is used throughout the EV industry to manufacture highly precise components that adhere to strict design parameters and compliance regulations. EV stamping processes are incredibly versatile and customizable, meaning manufacturers can produce a wide range of parts in nearly any size. Some of the most common applications of EV metal stamping include the following:

- A-frames

- Battery trays

- Body in white (BIW) components

- Brackets

- Brake parts

- EV battery parts

- EV charging parts

- Floor panels

- Heat shields

- Seating components

- Transmission systems and components